Design & Engineering

Smart UQ

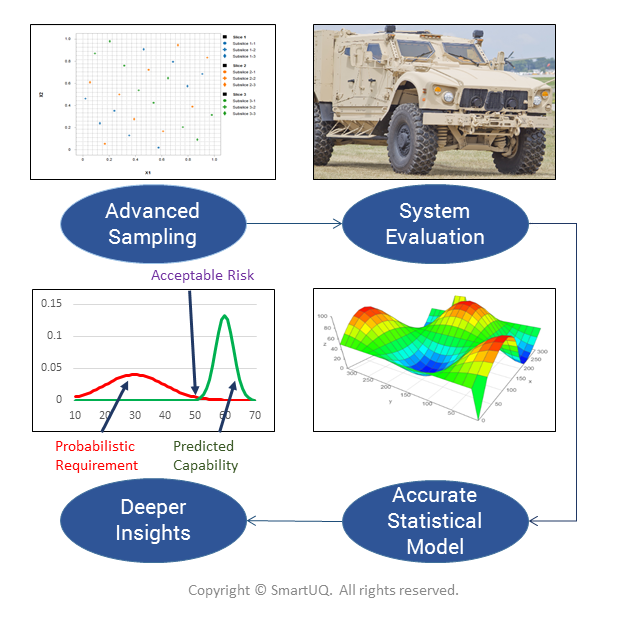

SmartUQ is a Machine Learning and AI tool optimized for engineering applications from ideation and design to manufacturing and sustainment. By providing powerful tools and highly accurate models with user-friendly GUIs and APIs, SmartUQ makes it easy to perform predictive modeling, optimized sampling, uncertainty quantification, and model calibration.

Why Choose Smart UQ ?

SmartUQ’s combination of unique sampling capabilities, powerful machine learning tools, and easy to use analytics help customers solve previously unsolvable problems. From Fortune 500 manufacturers to startups and engineering consulting firms, SmartUQ’s best in class predictive modeling accuracy helps customers go beyond analysis to bring uncertainty into the decision-making process.

A Variety Of Uses

Industries Served

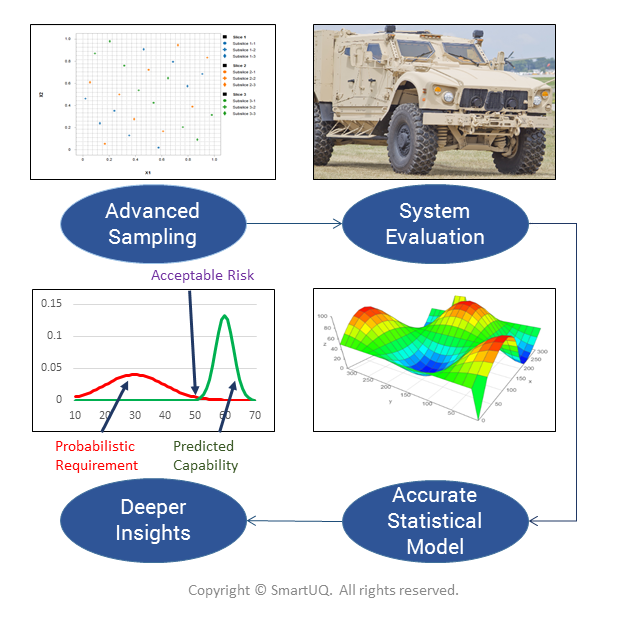

Aerospace & Defense

Turbomachinery

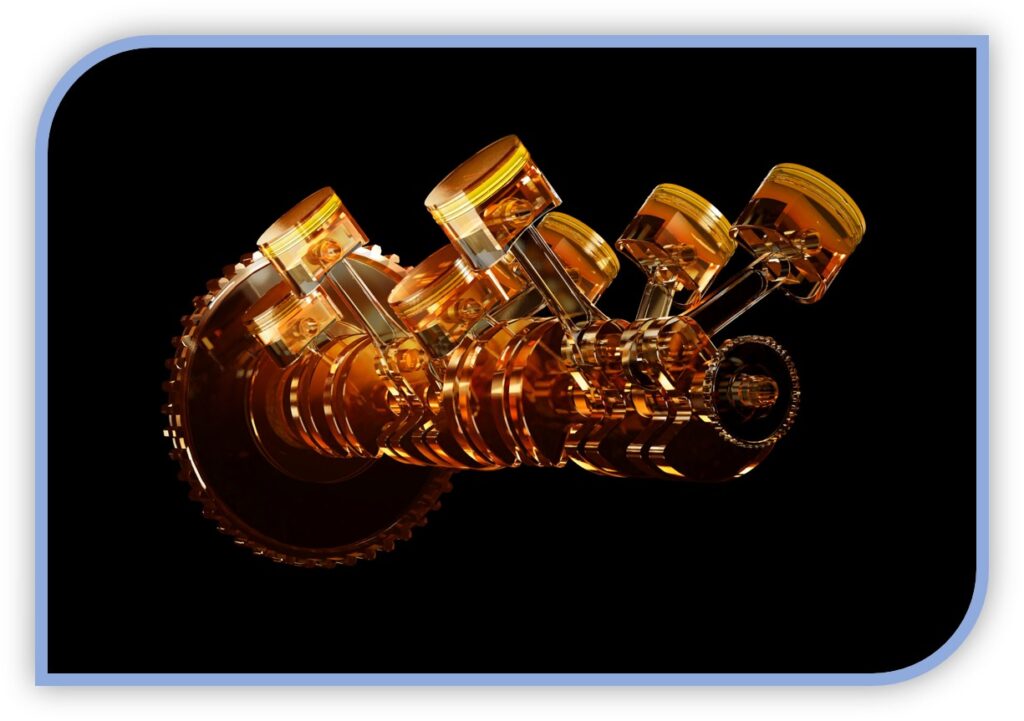

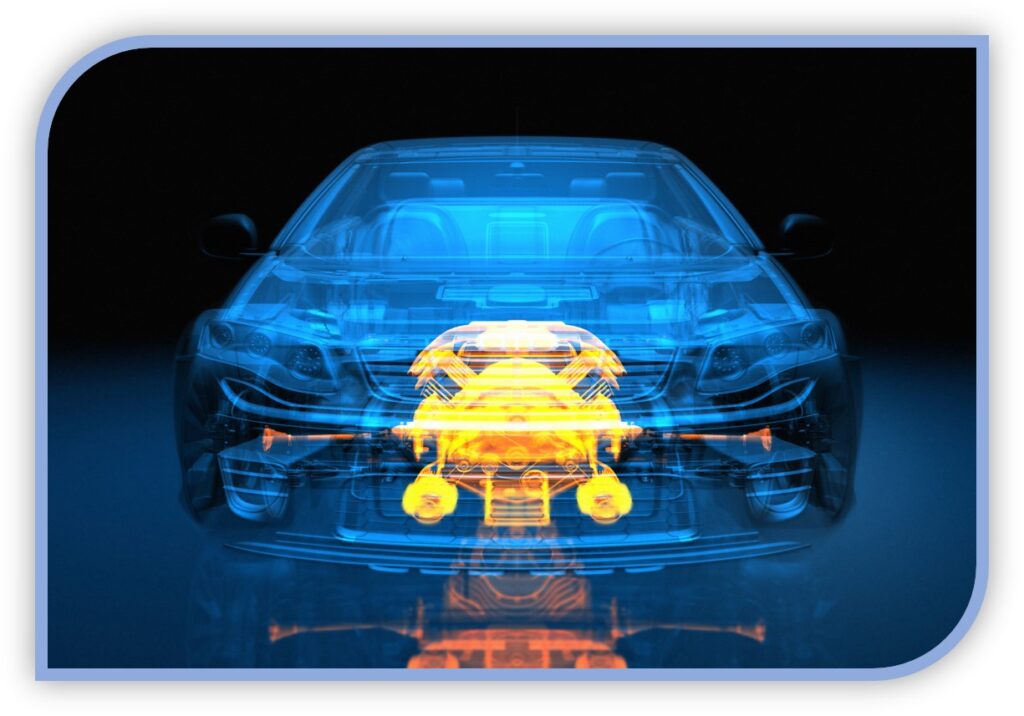

Automative

Heavy Equipment

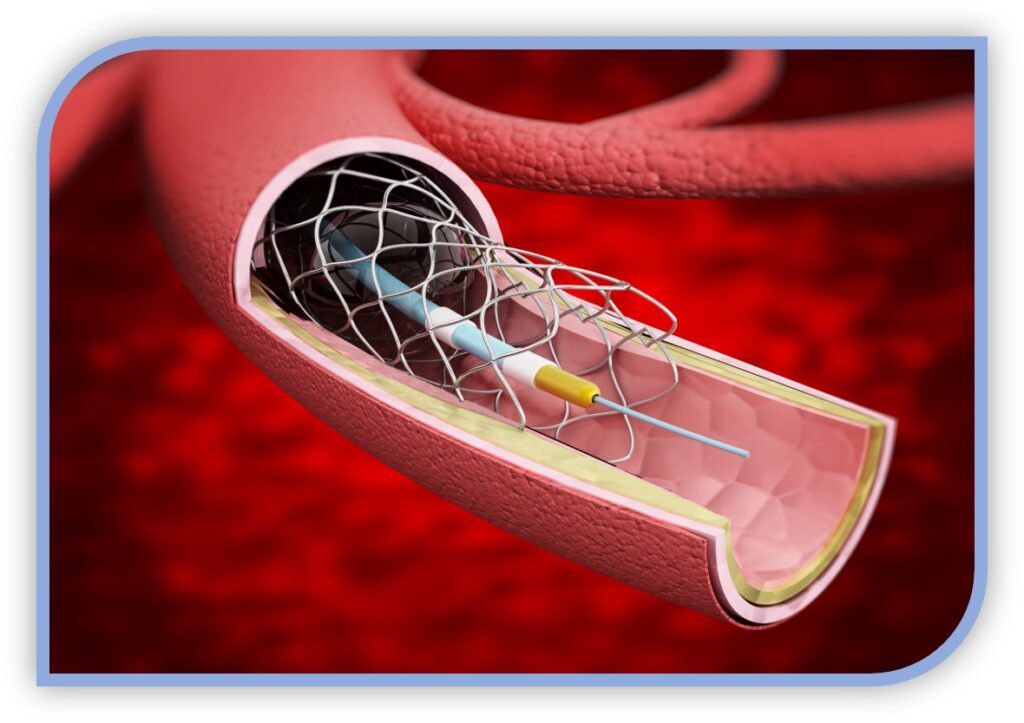

Medical Equipment

Consumer Electronics

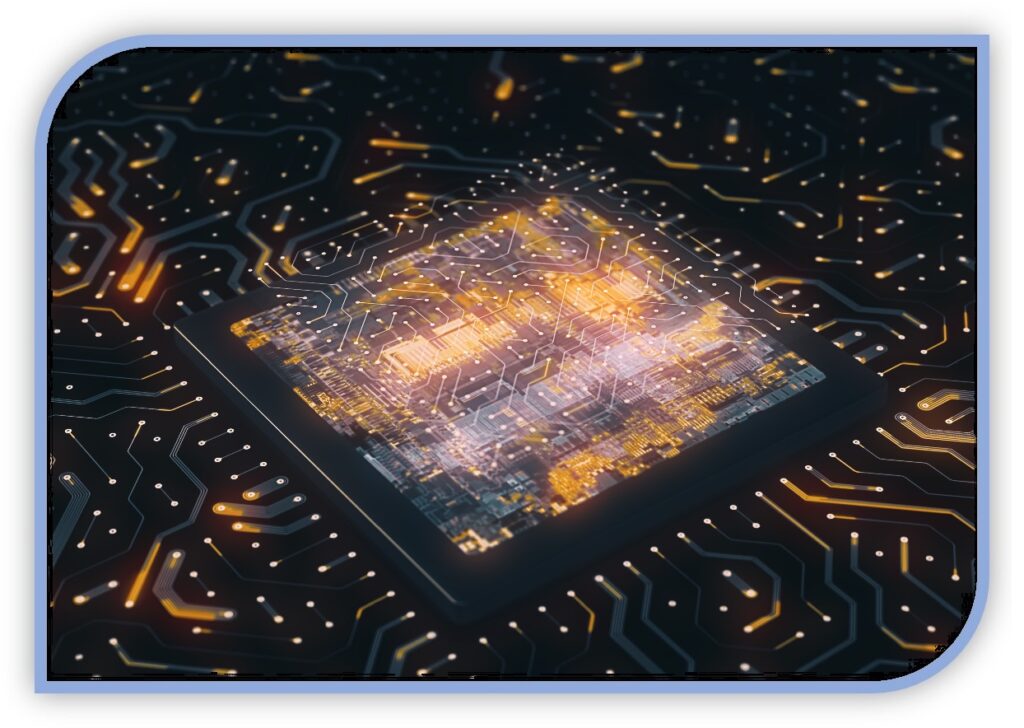

Semiconductors

HVAC

Energy, Oil & Gas

Tools & Application Uses

- Acceleration of simulation efforts

- Uncertainty Analysis

- Testing and evaluation planning

- Optimization under uncertainty

- Robust design

- Model calibration and validation

- Embedded models

- Virtual sensors

- Root cause analysis

- Manufacturing analytics

- Digital twin analytics

- Predictive Maintenance

- Quality Control

- Process Optimization

Featured Customers

Key Capabilities

- Design of Experiments

- Machine Learning

- Sensitivity Analysis

- Propagation Uncertainty

- Optimization Uncertainty

Design of Experiments

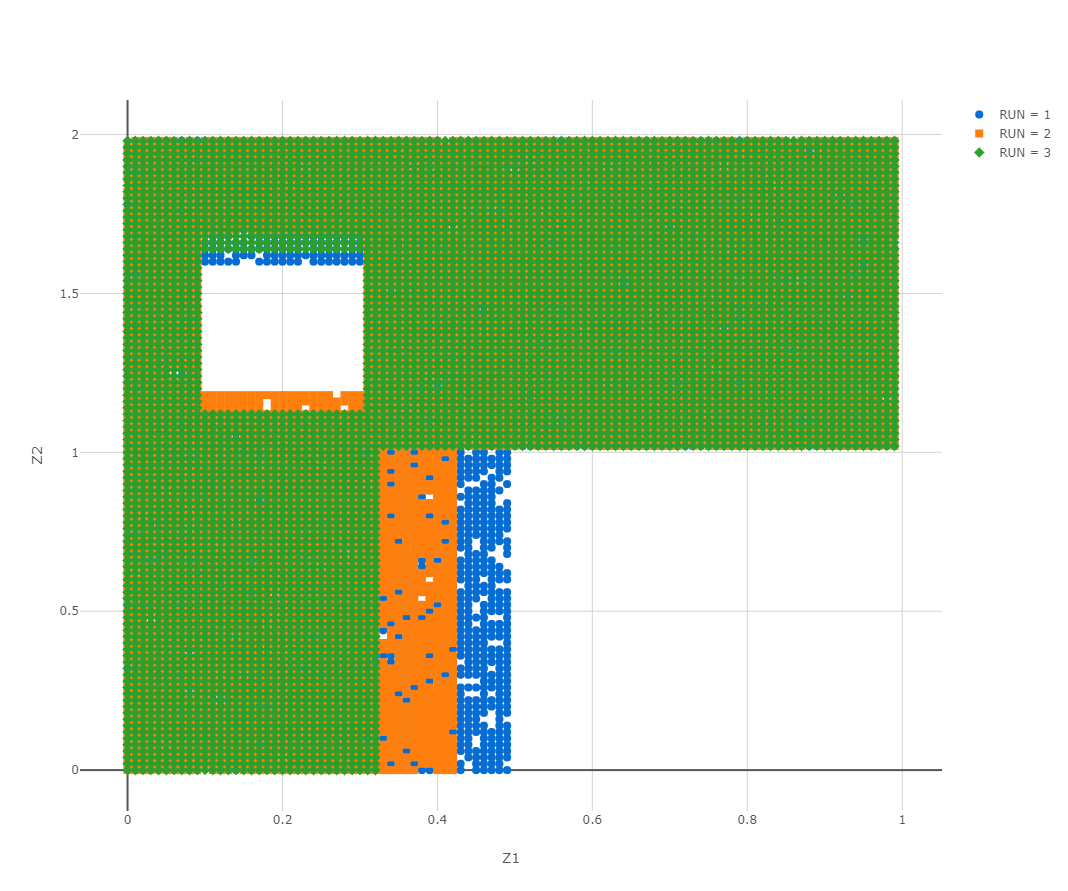

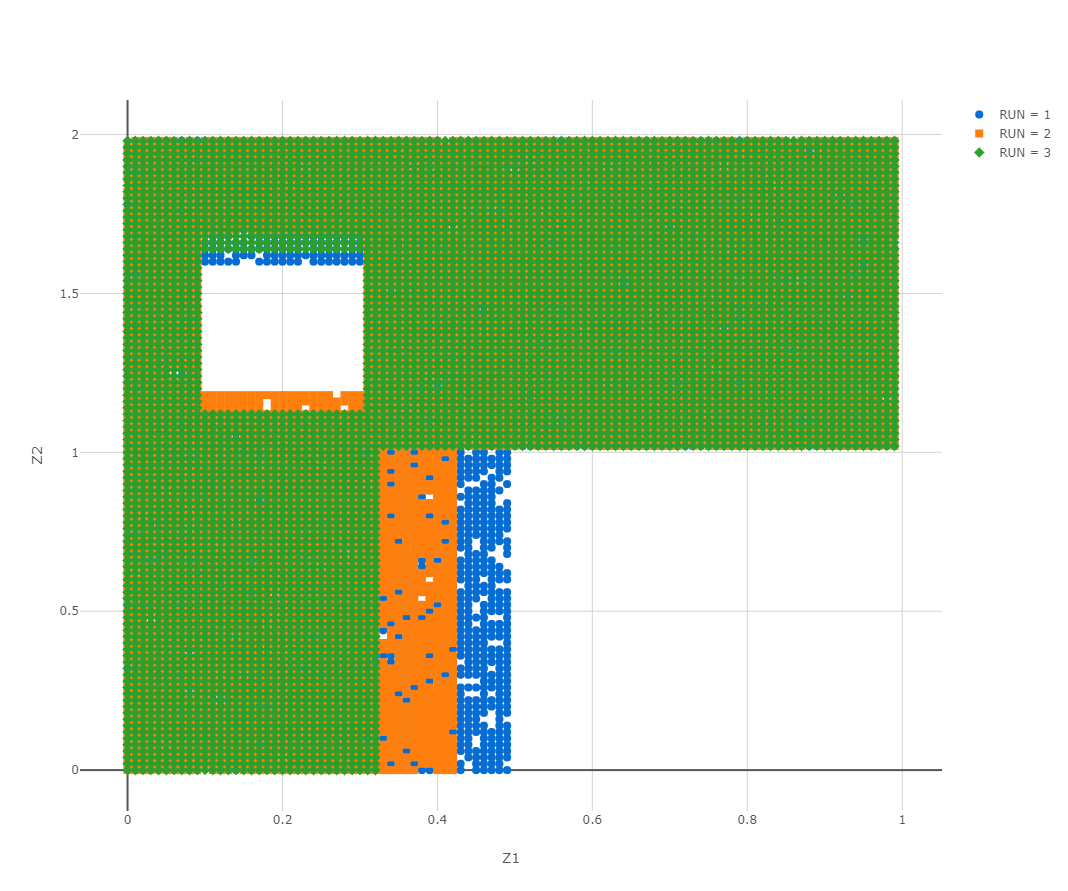

SmartUQ provides a number of breakthrough data sampling techniques and a comprehensive library of advanced DOE generators for both simulation and physical experiments.

Invented by thinking outside the box, our technologies ensure accuracy and minimize the number of data points required to generate uncertainty quantification and analytics results.

Several of our more popular tools include subsampling for Big Data applications and Adaptive Design, which maximizes sampling efficiency by using already gathered data to select additional data points.

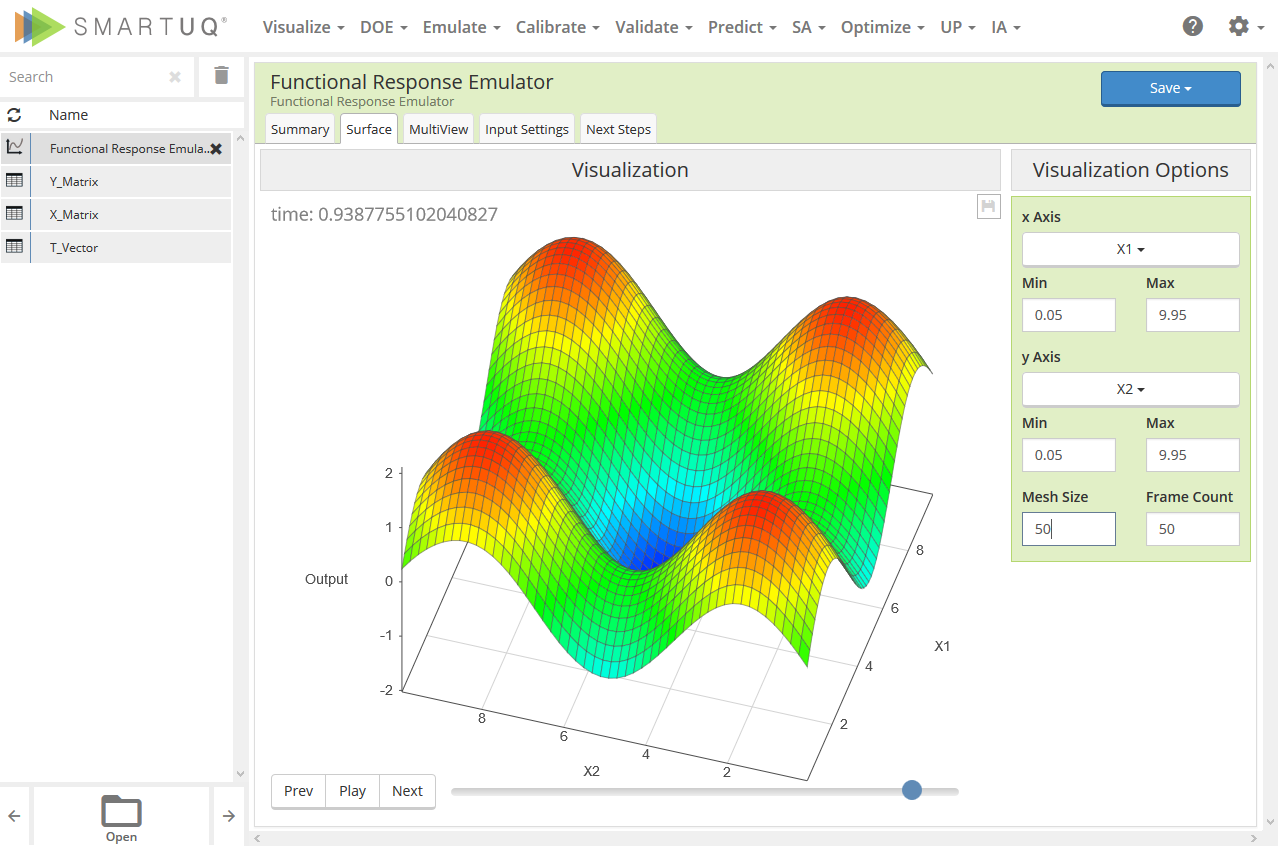

Emulation and Machine Learning

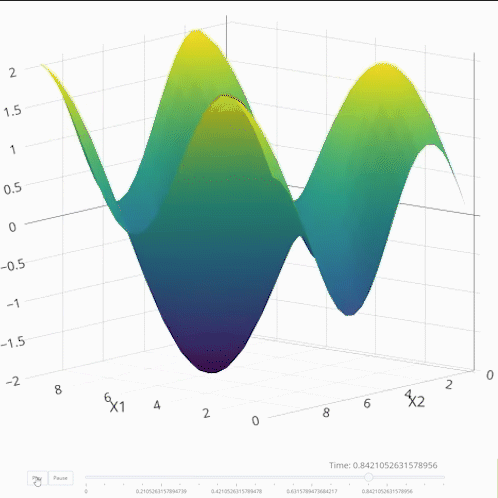

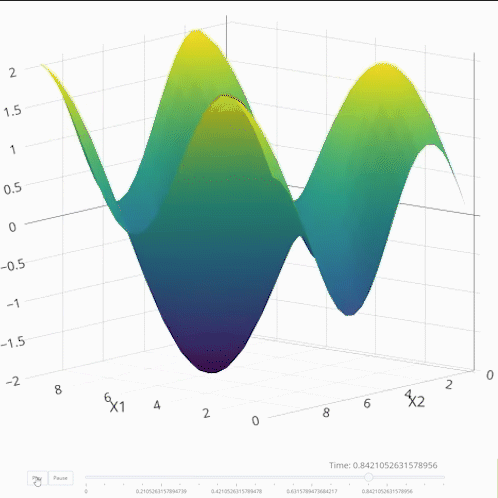

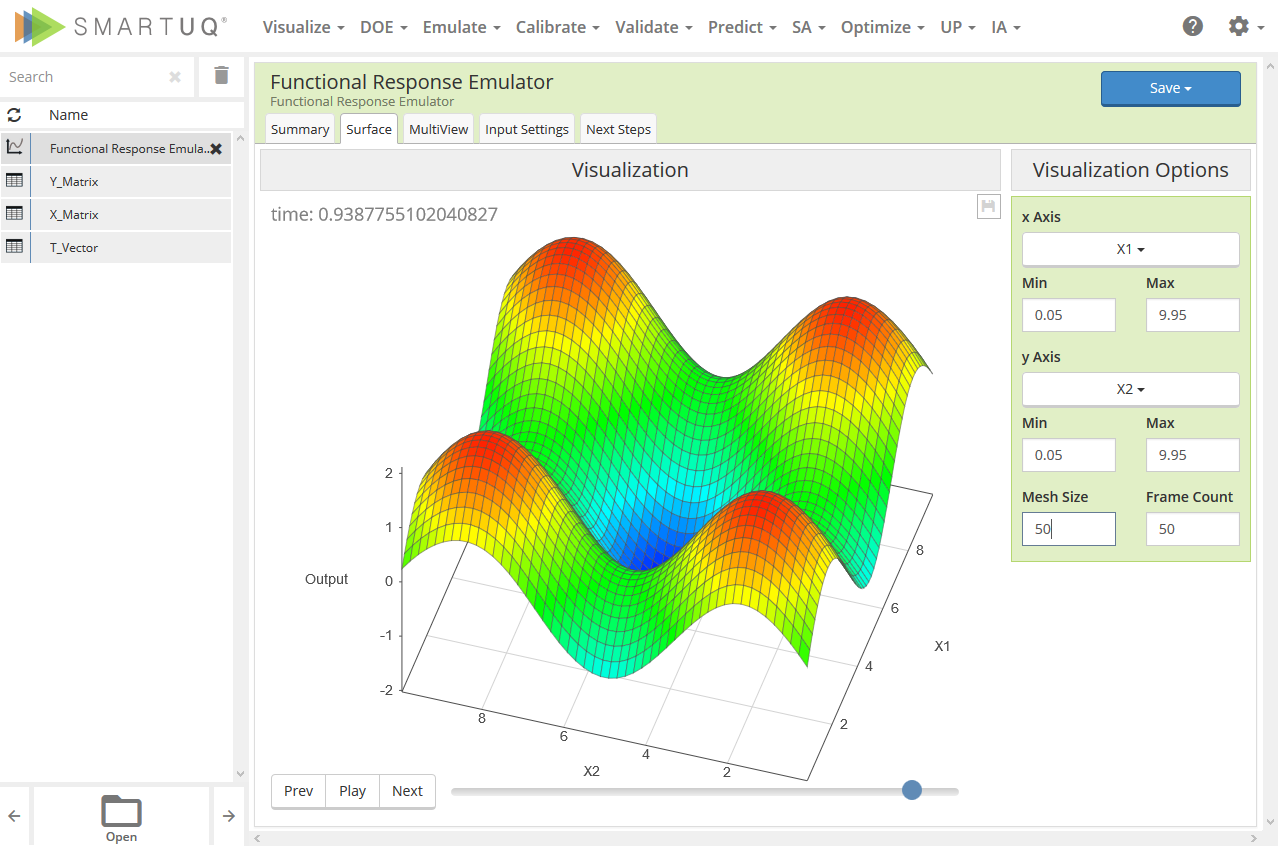

Game-changing emulation technology allows SmartUQ to fit accurate emulators in record-setting time.

These extremely fast analytical models can predict the behavior of complex black-box computational and physical systems.

Using emulators enables extremely fast uncertainty propagation, sensitivity analysis, design space exploration, statistical optimization, statistical calibration, and inverse analysis.

No more expensive Monte Carlo sampling and no more waiting hours for analytics calculations.

SmartUQ’s technology can handle categorical and continuous inputs, systems with multiple and functional outputs, high dimensional systems, and big data, opening new doors for accelerating uncertainty quantification and analytics.

Sensitivity Analysis

Rapidly determine the sensitivity of outputs with respect to inputs across the entire design space.

This is useful when determining sensitivity of part geometries, instrumentation accuracy, and regulatory compliance with respect to manufacturing tolerances, environmental conditions, and wear levels.

Sensitivity analysis shows which factors have a relatively low or high impact, allowing engineers to focus design effort and resources where they are needed most.

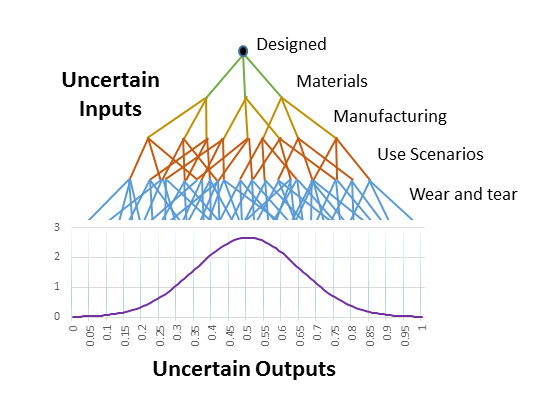

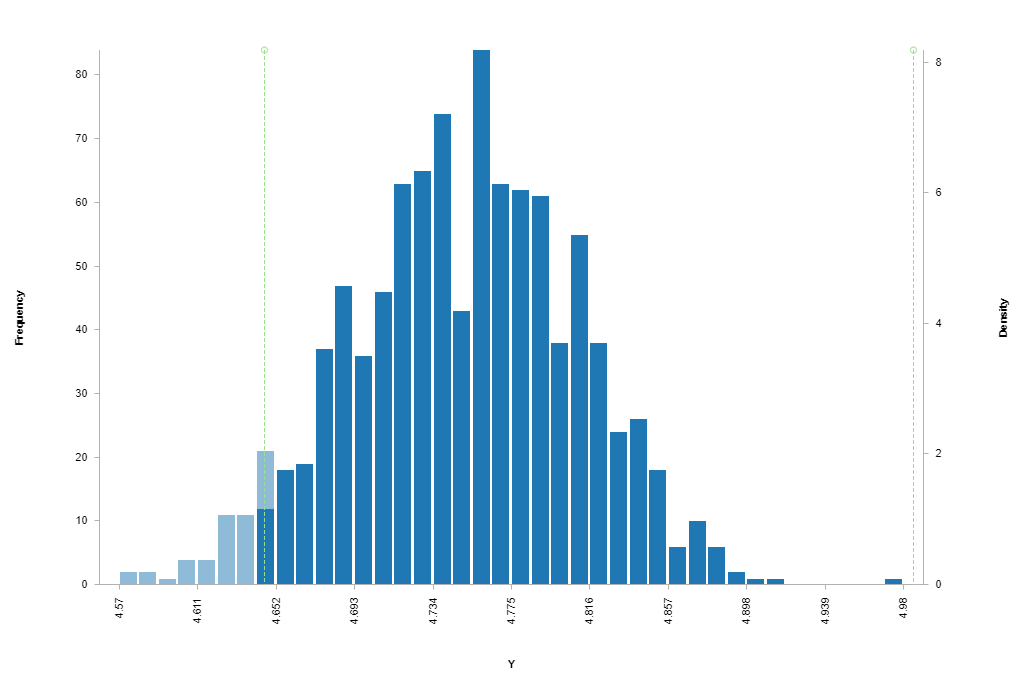

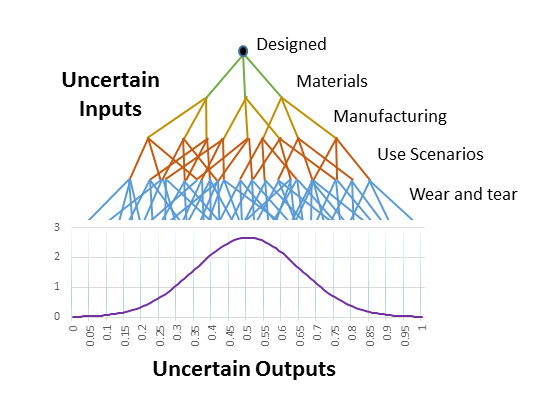

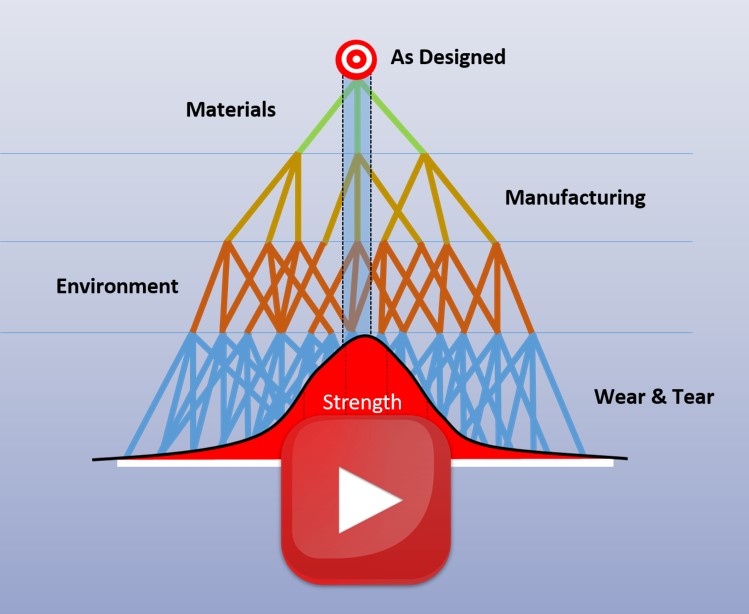

Propagation of Uncertainty

Propagation of uncertainty lets users predict the probability distributions of system outputs resulting from distributions of uncertain or variable system inputs.

Almost all systems have some input uncertainty usually from inputs like physical measurements, manufactured dimensions, material properties, environmental condition, and applied forces.

Propagation of uncertainty helps engineers determine whether the system outputs will meet requirements, what the extreme probabilities really are, and which inputs have the most effect on the output distributions.

All this means better initial designs, faster development, and simplified trouble shooting.

Optimization Under Uncertainty

SmartUQ can be used to conduct statistical optimization.

This novel approach combines adaptive sampling techniques and analytical models providing improved performance on complex problems relative to search based methods.

Statistical optimization also allows very rapid search area reduction with multiple objectives and very large numbers of input parameters.

Even better, the required system evaluations may be determined using adaptive design, recycled from earlier data sets, or run in parallel batches for large clock-time savings and shortened testing cycles.

Key Capabilities

- Design of Experiments

- Machine Learning

- Sensitivity Analysis

- Propagation Uncertainty

- Optimization Uncertainty

Design of Experiments

SmartUQ provides a number of breakthrough data sampling techniques and a comprehensive library of advanced DOE generators for both simulation and physical experiments.

Invented by thinking outside the box, our technologies ensure accuracy and minimize the number of data points required to generate uncertainty quantification and analytics results.

Several of our more popular tools include subsampling for Big Data applications and Adaptive Design, which maximizes sampling efficiency by using already gathered data to select additional data points.

Emulation and Machine Learning

Game-changing emulation technology allows SmartUQ to fit accurate emulators in record-setting time.

These extremely fast analytical models can predict the behavior of complex black-box computational and physical systems.

Using emulators enables extremely fast uncertainty propagation, sensitivity analysis, design space exploration, statistical optimization, statistical calibration, and inverse analysis.

No more expensive Monte Carlo sampling and no more waiting hours for analytics calculations.

SmartUQ’s technology can handle categorical and continuous inputs, systems with multiple and functional outputs, high dimensional systems, and big data, opening new doors for accelerating uncertainty quantification and analytics.

Sensitivity Analysis

Rapidly determine the sensitivity of outputs with respect to inputs across the entire design space.

This is useful when determining sensitivity of part geometries, instrumentation accuracy, and regulatory compliance with respect to manufacturing tolerances, environmental conditions, and wear levels.

Sensitivity analysis shows which factors have a relatively low or high impact, allowing engineers to focus design effort and resources where they are needed most.

Propagation of Uncertainty

Propagation of uncertainty lets users predict the probability distributions of system outputs resulting from distributions of uncertain or variable system inputs.

Almost all systems have some input uncertainty usually from inputs like physical measurements, manufactured dimensions, material properties, environmental condition, and applied forces.

Propagation of uncertainty helps engineers determine whether the system outputs will meet requirements, what the extreme probabilities really are, and which inputs have the most effect on the output distributions.

All this means better initial designs, faster development, and simplified trouble shooting.

Optimization Under Uncertainty

SmartUQ can be used to conduct statistical optimization.

This novel approach combines adaptive sampling techniques and analytical models providing improved performance on complex problems relative to search based methods.

Statistical optimization also allows very rapid search area reduction with multiple objectives and very large numbers of input parameters.

Even better, the required system evaluations may be determined using adaptive design, recycled from earlier data sets, or run in parallel batches for large clock-time savings and shortened testing cycles.

8 Reasons Why

Using all types of data sets a trained SmartUQ predictive model can quickly perform complex analysis: giving your team a competitive advantage.

- Virtual Sensors & Predictive Maintenance

- Reduce Simulation Demand

- Root Cause Analysis

- Model Calibration & Validation

- Digital Twins

Tasks such as geometry optimization, tolerance analysis, calibration to physical measurements, and uncertainty quantification on spatial responses all require handling varying geometries.

SmartUQ's Changing Geometry Emulator extends the capabilities of SmartUQ's spatial emulation to capture the effects of inputs on spatial responses and the effects of inputs on the resulting geometry or mesh.

This opens up fast and accurate surrogate modeling for all kinds of simulations and spatial meassurments.

No matter where the data comes from - simulation, physical testing, sensors, or a digital twin - there always is an element of uncertainty.

By using Uncertainty Quantification to consider all the possible outcomes, you can optimize your decision making process resulting in reduced risk and greater confidence in your results.

See how SmartUQ optimizes decision-making from all data types, including:

- Additive Manufacturing

- Digital Twins

- Virtual Sensors

- Simulation

SmartUQ can help you get the most information out of the fewest points:

- Optimize sampling of new data while making use of existing data.

- Create balanced space filling samples while making use of existing data.

- Direct sampling to refine data sets only where necessary.

- Explore the entire design space through accurate emulation

- Save time and resources by reducing design and testing iterations.

We provide a wide spectrum of capabilities including:

- Design of experiments

- Emulation

- Statistical calibration

- Sensitivity analysis

- Propagation of uncertainty

- Statistical optimization

- Inverse analysis

- Take advantage of analytics to gain deeper insights and create better products faster.

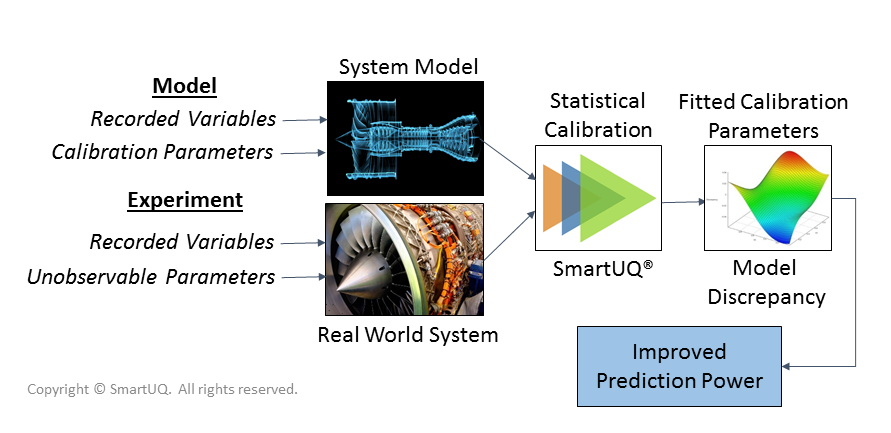

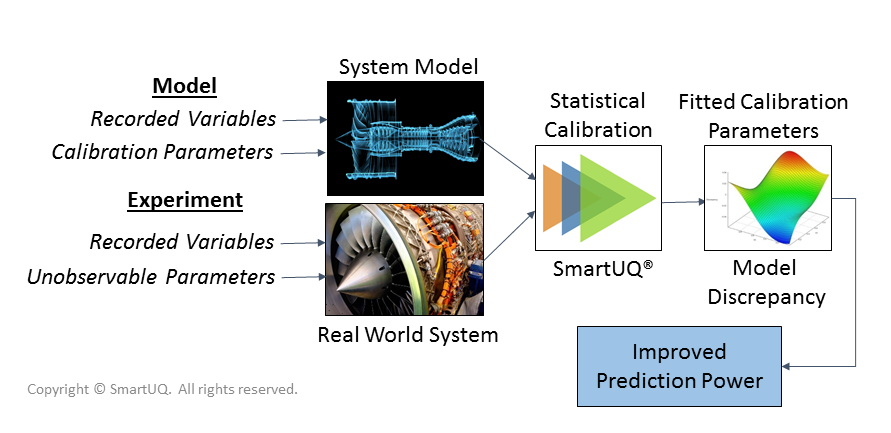

Calibration is necessary when building models in order to improve the fidelity or prediction ability of the simulation. SmartUQ features dedicated tools to facilitate model calibration including specialized hybrid design-of-experiments generators and automated statistical calibration. Improve model validation by quickly finding best-fit parameters and confidently assessing model discrepancies.

7. Statistical Calibration: Ground Simulations in Physical Data

Uncertainty is part of every system. It arises from measurement accuracies, material properties, use scenarios, modeling approximations, and unknown future events. Uncertainty in model boundary conditions, initial conditions, and parameters makes it harder to answer your most important questions with confidence: Will it meet all the requirements and is it optimal?

8. Uncertainty is Everywhere8 Reasons Why

- Building predictive models are trained to mimic complex engineering simulations.

- Sensitivity Analysis which ranks parameters by their ability to influence the results.

- Statistical Calibration which handles the disagreement and uncertainty between the simulation model and physical tests.

- Inverse Analysis determines an underlying

distribution for ill-conditioned and sparse model input.

Using all types of data sets a trained SmartUQ predictive model can quickly perform complex analysis: giving your team a competitive advantage.

- Virtual Sensors & Predictive Maintenance

- Reduce Simulation Demand

- Root Cause Analysis

- Model Calibration & Validation

- Digital Twins

Tasks such as geometry optimization, tolerance analysis, calibration to physical measurements, and uncertainty quantification on spatial responses all require handling varying geometries.

SmartUQ's Changing Geometry Emulator extends the capabilities of SmartUQ's spatial emulation to capture the effects of inputs on spatial responses and the effects of inputs on the resulting geometry or mesh.

This opens up fast and accurate surrogate modeling for all kinds of simulations and spatial meassurments.

No matter where the data comes from - simulation, physical testing, sensors, or a digital twin - there always is an element of uncertainty.

By using Uncertainty Quantification to consider all the possible outcomes, you can optimize your decision making process resulting in reduced risk and greater confidence in your results.

See how SmartUQ optimizes decision-making from all data types, including:

- Additive Manufacturing

- Digital Twins

- Virtual Sensors

- Simulation

SmartUQ can help you get the most information out of the fewest points:

- Optimize sampling of new data while making use of existing data.

- Create balanced space filling samples while making use of existing data.

- Direct sampling to refine data sets only where necessary.

- Explore the entire design space through accurate emulation

- Save time and resources by reducing design and testing iterations.

We provide a wide spectrum of capabilities including:

- Design of experiments

- Emulation

- Statistical calibration

- Sensitivity analysis

- Propagation of uncertainty

- Statistical optimization

- Inverse analysis

- Take advantage of analytics to gain deeper insights and create better products faster.

Calibration is necessary when building models in order to improve the fidelity or prediction ability of the simulation. SmartUQ features dedicated tools to facilitate model calibration including specialized hybrid design-of-experiments generators and automated statistical calibration. Improve model validation by quickly finding best-fit parameters and confidently assessing model discrepancies.

7. Statistical Calibration: Ground Simulations in Physical Data

Uncertainty is part of every system. It arises from measurement accuracies, material properties, use scenarios, modeling approximations, and unknown future events. Uncertainty in model boundary conditions, initial conditions, and parameters makes it harder to answer your most important questions with confidence: Will it meet all the requirements and is it optimal?

8. Uncertainty is EverywhereRead What Others Think

“SmartUQ has the best prediction accuracy among all tools I have ever used.”

“Our Uncertainty Quantification discipline now uses SmartUQ as its central tool and with it we have helped save millions of dollars and thousands of hours of work.”

“SmartUQ’s adaptive design can significantly reduce the number of required simulations [a 72% reduction] and lead to much higher model accuracy [96% reduction in reference prediction error]”

- Related Case Studies

- Building predictive models are trained to mimic complex engineering simulations.

1. UQ Goes Beyond Uncertainty Propagation- Sensitivity Analysis which ranks parameters by their ability to influence the results.

- Statistical Calibration which handles the disagreement and uncertainty between the simulation model and physical tests.

- Inverse Analysis determines an underlying distribution for ill-conditioned and sparse model input.